For rotation-symmetric items – high mechanical performance, economical and scalable

Filament Winding Technology

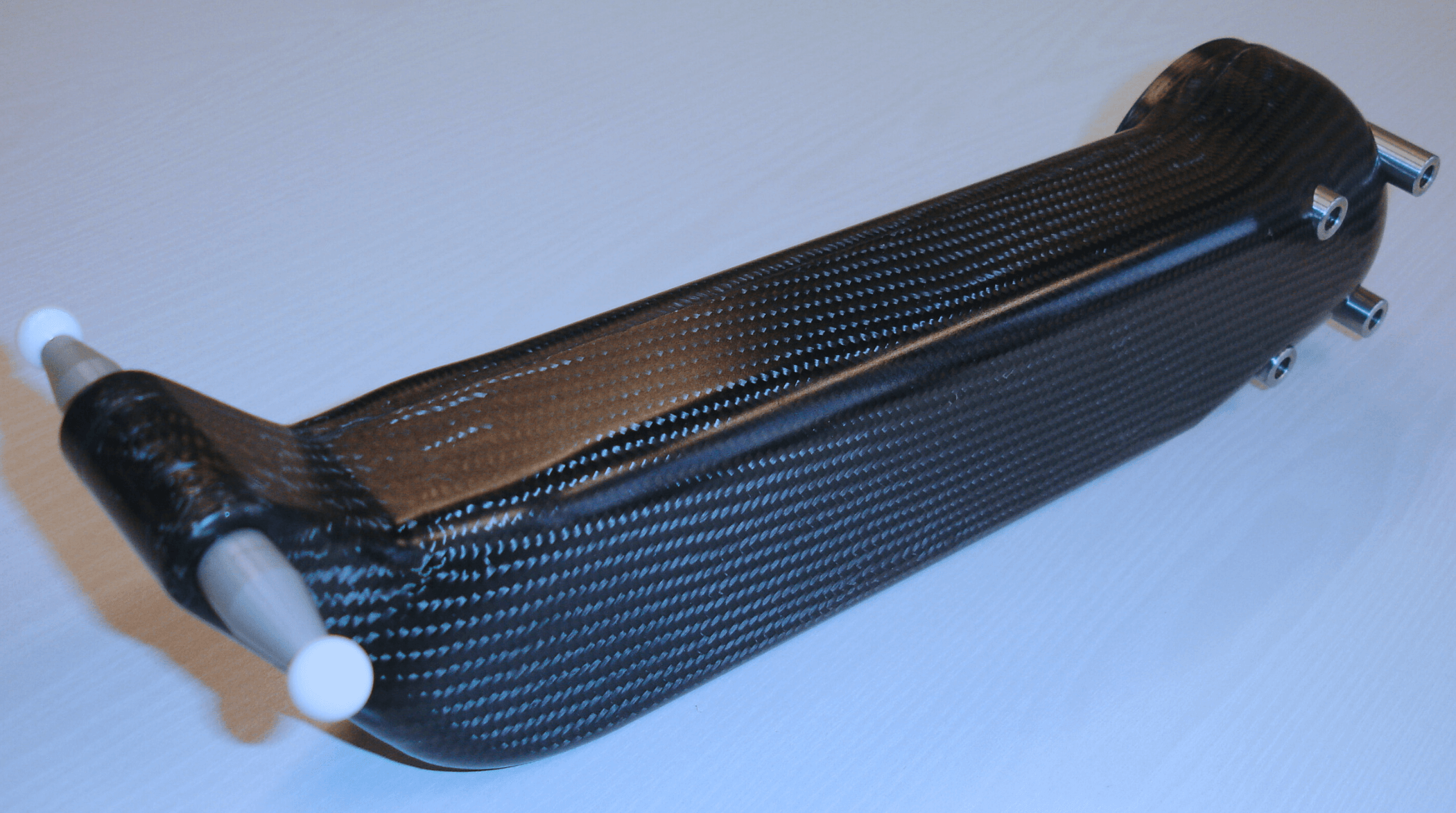

Wound components by Connova Group distinguish themselves to conventional components by superior mechanical characteristics, attractive unit costs, and a high process-stable scalability up to a high-volume production. The filament winding technology by Connova Group allows for a perfect and load-optimized laminate, which allows a high variety in part geometry. A light-weight design approach combined with high strength and high stiffness makes them ideal for highly loaded components, especially when a high endurance is required.

The continuous glass or carbon fibres (rovings) are mechanically impregnated in a resin tub and laid up onto a rotating mandrel by a numerically controlled machine set-up. The completely automatized production process guarantees a full traceability and highest quality of serial products. The so-called filament winding technology is particularly economic due to the high degree of automatization, the low labour cost and – compared to other production technologies – the extremely low waste of material. At the first place, the filament winding process is well suitable for rotation-symmetric items such as tubes, pipes, shafts, struts, bars, etc. and, finally, closed vessels and tanks.

Advantages of filament winding process are:

- Perfectly controlled fibre deposition

- Optimal mechanical properties

- Ideal fibre volume content

- Low porosity

- Low weight

- Low inertia of mass

- High stiffness

- Superior vibration damping

- Very low thermal expansion

In comparison to other CFRP parts made of woven fabrics, filament-wound parts attain up to 20% less weight providing comparable mechanical properties. The process is characterized by high accuracy and traceability. Even with small series, an economic and efficient unit cost is well achievable.

Typical applications of filament winding are:

- In e-mobility: rotor bands, partition shells

- In automotive: compression struts, actuators, drive shafts

- In aviation: struts, drive shafts, secondary structures

- In mechanics: tool extensions, guiding tubes, telescopic tubes, rolls, sleeves, bands

- In robotics: actuators

- In water management: pressure pipes, filter or rotor housings

Connova Group has the know-how and the means for filament winding technology:

- Multi-spindle numerically controlled (NC) winding machine providing four independently controllable axis

- Maximum winding length up to six meters

- Maximum winding diameter up to 600 millimetres

- Maximum weight per item up to 1,500 kg

- CAM programming and simulation of winding by software COMPOSICAD

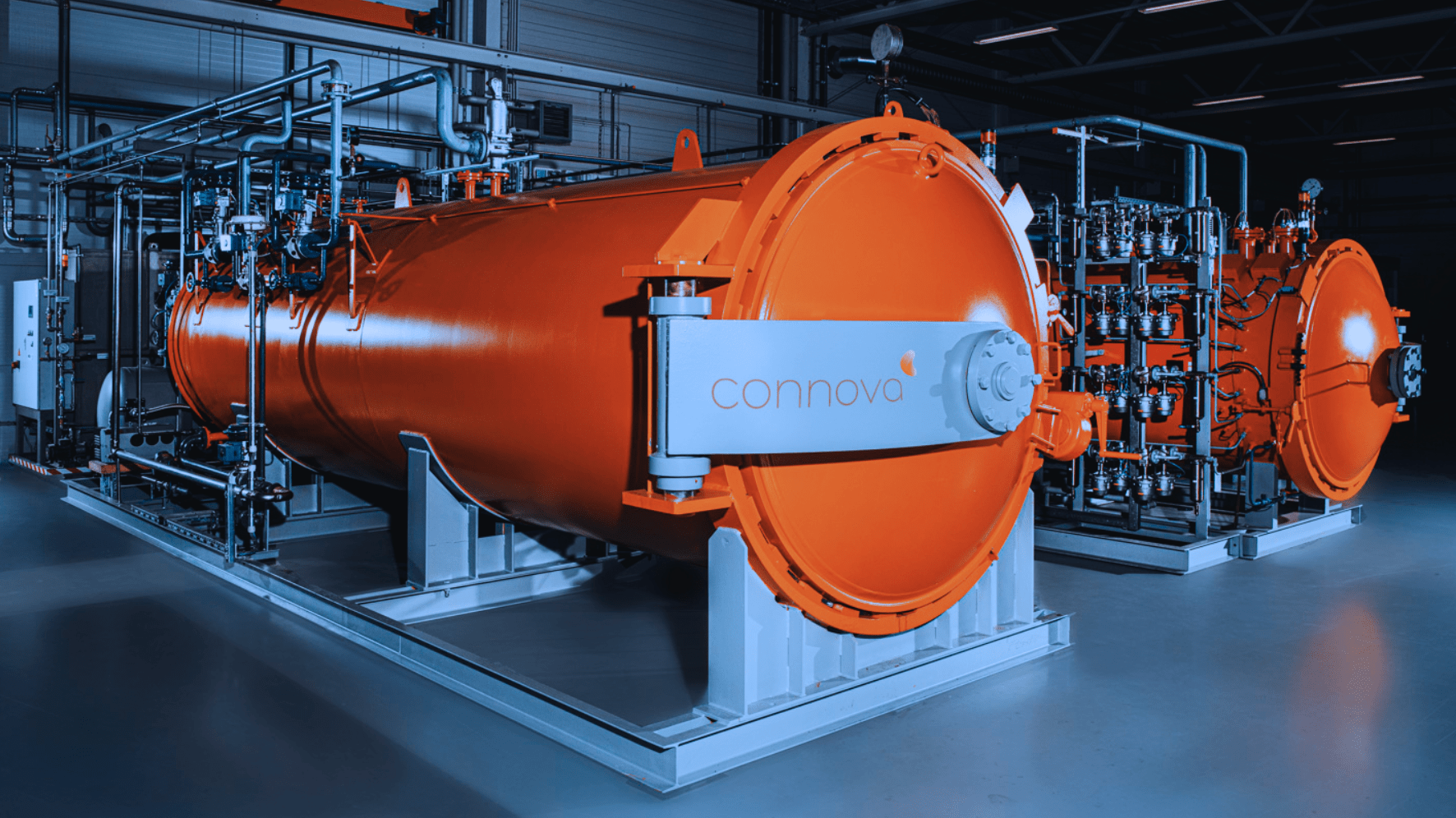

- Computer-controlled and automatized curing and tempering ovens

Our winding machine

A winding machine consists of a rotating device for the tool mandrel, thread guide and thread storage, and a resin bath that moves back and forth along the axis of rotation. With a revolutionary winding machine from the German world market leader “Roth”, Connova Group offers a stable and fail-safe component supply, especially for large-scale production of 10,000-100,000 components per year. The innovative process data monitoring system achieves an excellent level of process capability, so that new markets and applications can be mastered that previously were not accessible using filament winding technology.